Mercedes-Benz Bremen Factory Building #9- 09.28.11

On my adventure to see where my AMG C63 Coupé (like the one we tried on the track!) will come from, Shawn Sims joined me with his automotive and engineering expertise on the adventure to the factories to learn about the whole process. He rounded up our story in Bremen below for you!

On my adventure to see where my AMG C63 Coupé (like the one we tried on the track!) will come from, Shawn Sims joined me with his automotive and engineering expertise on the adventure to the factories to learn about the whole process. He rounded up our story in Bremen below for you!

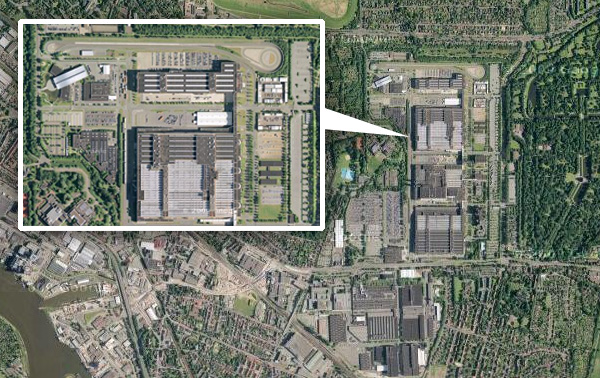

As we raced to the Mercedes-Benz factory along the Autobahn from Hamburg to Bremen, I couldn’t help but wonder what crazy German engineering mega-center we were about to stumble into. We arrive at the campus (more like small town) of the 15,000,000 sqft factory that has over 12,000 people inside. Starting at from the customer welcome center (where the GT5 set up greeted us and where you can pick up your new car directly), we first watch a video overview of how Mercedes’ are produced and get a peek at the people and machines behind them. Then we headed into Building 9; a pristine, lively, mechanical wonderland responsible for the production of the C-class (as well as a few others simultaneously). There are over 8.5 kilometers of assembly lines in Building 9 alone, and the majority are stations for assembly by hand. Each employee on the line is trained in multiple positions so that day to day work changes. Supply trucks are whizzing by, car bodies flying on overhead tracks, robots twisting and turning, all while the seemingly endless hall is filled with the sounds of motors, robots, drills, and presses. We have entered an engineering mecca!

Photos wouldn’t even do the mesmerizing process justice, so check out the great introduction video we saw (the robots really are quite incredible), as well as our pics and videos of the adventure on the next page.

Here’s the intro video we watched before diving in to the factory line itself.

As the car bodies are flying over head, the engine and chassis come sweeping in below. This is “The Wedding,” the moment where the body meets chassis and engine for the first time and it is something special to see in person. The two halves started in different buildings, days ago and with a few robotic precision bolts and welds, a Mercedes begins to take form.

It is certainly a magical place for a car enthusiast and machine-fiend. Check out the KUKA robots! Here the robots are placing on the panoramic sunroof and bolting in dashboard pieces. It is only fitting for German robots to build German cars.

Here is the car’s first start! It takes a moment to pump the fuel lines, but after a few seconds the machine comes to life. This is the last step in the Building 9 before the car makes its way to testing and quality control.

And as for where cars go in between these stages… they travel by tunnel/bridges between factory buildings!