Fritz Hansen’s NAP chair by Kasper Salto- 05.09.10

Spotted across the street when we were in Milan ~ Fritz Hansen had an incredible display not only showcasing the new NAP chair by Kasper Salto… but the whole process, from inspiration boards to prototypes to failed tests and more! It’s an inspiring way to see how much work and testing goes into a product that ends up so simple, functional, and beautiful. See the full walk through on the next page!

Spotted across the street when we were in Milan ~ Fritz Hansen had an incredible display not only showcasing the new NAP chair by Kasper Salto… but the whole process, from inspiration boards to prototypes to failed tests and more! It’s an inspiring way to see how much work and testing goes into a product that ends up so simple, functional, and beautiful. See the full walk through on the next page!

Fritz Hansen timeless aesthetic, discreet luxury and functionalism are very well suited for today’s demand for relevant design.They are focusing on well being and comfort and it shows with their new addition.

After 2 years in the making they’ve released NAP , a chair created by Danish furniture designer Kasper Salto. His aim was to make the NAP chair functional without compromising on appearance- just like the great designers of the past like Arne Jacobsen.

At first glance the chair may look too simple and identifiably Fritz Hansen, but when you take a closer look you notice the forward looking curves and texture. It is then when you have to nod and agree that god is in the details.

The name of the chair reflects Kasper’s mentality. NAP stands for normal, active and passive. Normal means sitting up straight, all the way back into the seat. Active is when we are leaning forward to listen or speak, eat or work at a table. Passive means leaning back and relaxing.AP

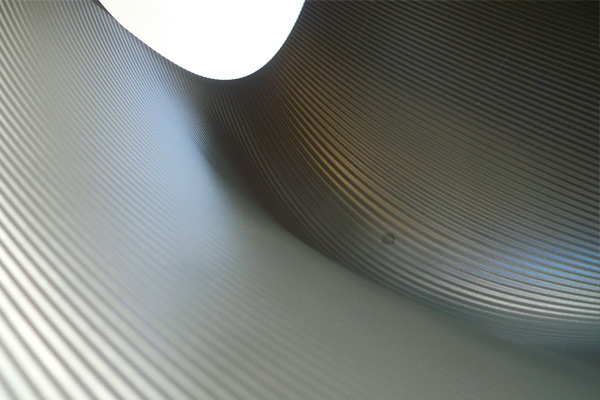

“Nap” design process samples, CNC machined in “Renshape” ( a modeling material), made in order to test basic geometries, functionality and the appearance of the grooves Also there’s a vacuum suction mold, CNC machined in “Renshape” too for the first tests of a full scale model.

Results of vacuum suction mould before and after “cut-out” in 6mm polupropylene (PP). Made in order to test seating positions. and next to those a Shell without arm in Polyamide (PA). The final surface treatment is missing however, made to adjust final details.

Arm testing machine,used according to EN 15373, Non Domestic Seating, test level 2, general contract use, clause 13 durability of arms. Minimum requirement is 50,000 cycles. The load on the machine in total is 80 kg (176 lbs) = 40 kg (88 lbs) per arm.

Short shots to test whether the tool is filled up properly, clarification of how the plastic is working in final casting mold.