NOTlabs: Rabbit Laser Cutter Unboxing- 07.09.12

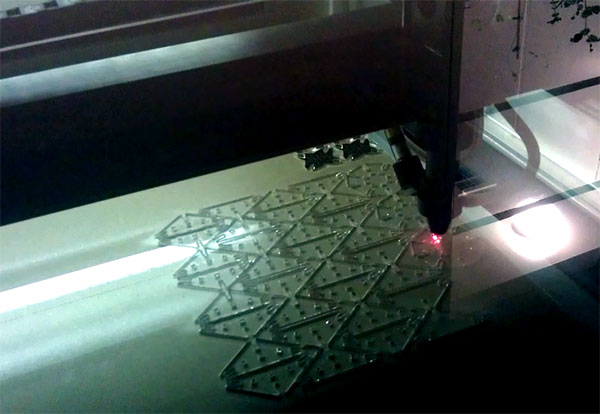

LASERS! NOTlabs is now outfitted with a Rabbit Laser 80-1290 laser cutter that has an 80 Watt laser tube and a 4’x3’ cutting area! This (in combination with our Makerbot) means we can create 2D+3D designs and start cutting, prototyping, and playing with them immediately. The machine works by bouncing a laser beam off of 3 mirrors to a focusing lens that directs the beam downwards into the material. Essentially it is an extremely precise and powerful upgrade from our hand held X-acto knifing that can cut through things such as 1/2” wood or acrylic. Since the beam is very thin we are able to make very precise cuts, as well as etch intricate details (like the etching you’ve seen on moleskines, MacBooks, etc.)

We explored whether to build our own (i.e. LASERSAUR), or go for a smaller Epilog or Universal laser cutter which Shawn has worked with extensively in the past… and the Rabbit Laser 1290 model with an 80 Watt laser tube was the best option. It’s been nice having the 10” Z-height as well as a pass through for when we want to send larger objects through the machine. It can reach up to 1000 dpi (which is plenty since we’re focusing on cutting versus engraving). On nice design details, the parts tray is a great catchall below the workbed which you can easily slide out to empty scraps or find valuables which may have fallen through.

The story behind Rabbit Laser USA distribution is a fascinating one: short story being that Ohio engineer, Raymond Scott, was looking for the best quality with greater affordability and when ordering his own, ended up taking over a full shipment of machines (which he then needed to sell), learning about importing/customs(re)crating/etc, and exploring the factories in China, and more… and a few years later, it has evolved into a family business, where he and his wife Carol (and even his young daughters help out!) have a warehouse in Ohio, carefully inspect and test each machine that comes in, they come out and personally install the machines and train you for a day with each purchase, and have a great feedback loop with King Rabbit in China to constantly improve the design details and software needs for the laser cutters. In the day that Ray came out, i learned more than i ever imagined about not only how a laser cutter works and how to take care of it, but so much about the business side and interaction with the King Rabbit manufacturing standards, facilities, and more as well. But back to the UNBOXING… or uncrating, rather… it was quite the adventure, so take a peek on the next page to see the uncrating and setup!

The 1100lb crate showed up on a truck… with one guy driving. And no fork lift.

… somehow he and Shawn got it off the truck and into the garage.

We uncrated it… making it only 660lbs… took all the boxes out from inside of it… and then had to use car jacks to maneuver it off the palette… remove one of the panels of the fence as well as a panel of the sliding glass door… to roll it inside to its room.

Inside! Once in, Ray from Rabbit Laser USA distribution flew out from Ohio for the day to setup the machine and give us basic training…

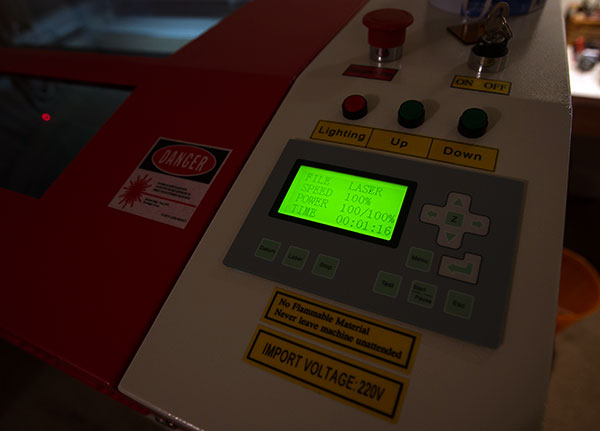

Here’s the main control panel ~ you simply connect your computer to it via USB.

Love this huge emergency stop button…

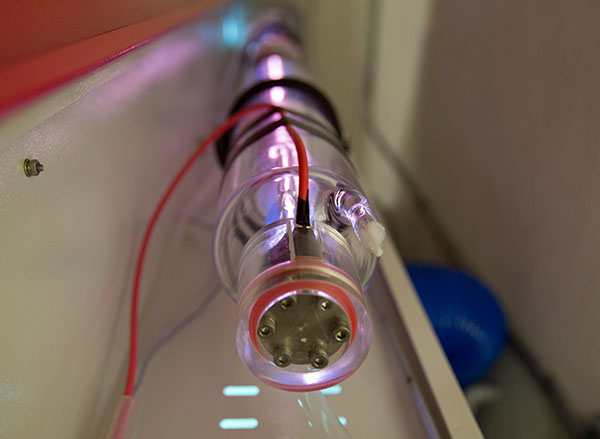

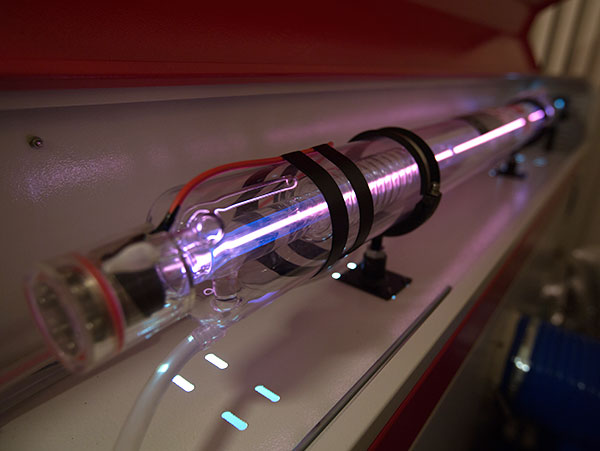

Lasers!!!

This engrish warning label inside the machine was too funny not to share!

This industrial chiller cools keeps the laser tube cool… (yes yes, the crazy exhaust tubing will get cleaned up soon!)

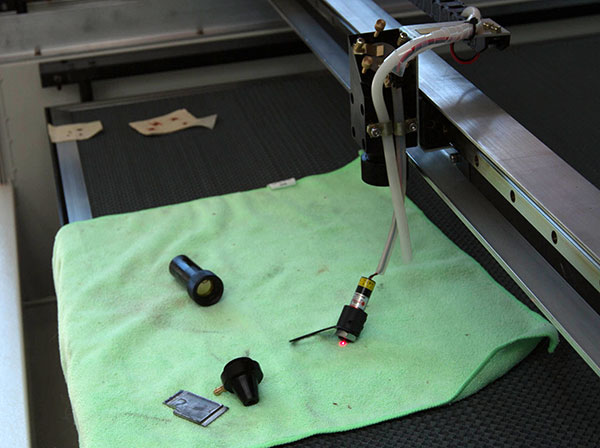

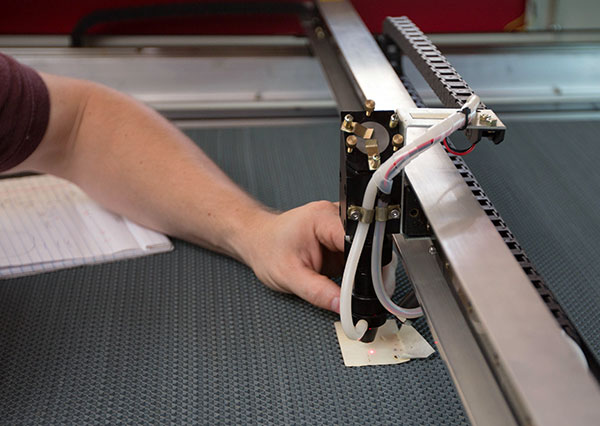

Cleaning the lens and mirrors before testing…

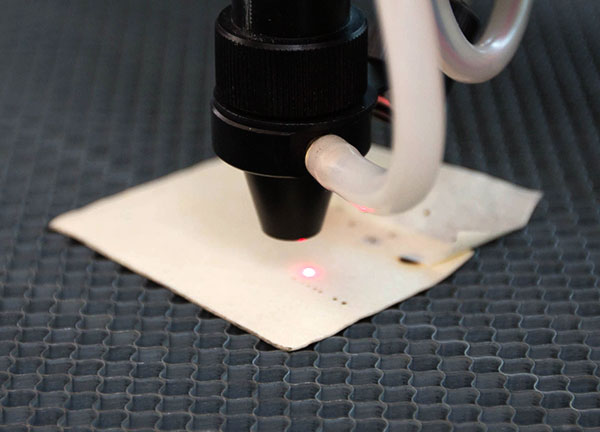

Laser testing to focus the laser…

And we’re cutting!!!

You can’t use just any fire extinguisher apparently ~ you need the dry CO2 ones… may we never need to use this!

Hey how is engraver treating you? I am about to pull the trigger for one of these and wanted to make sure you’re still loving it.

----- Jon Bybee 04.09.12 09:06