Unboxing: Roland MODELA Pro II MDX-540S- 05.30.15

There’s a CNC mill in NOTlabs! While Shawn has been playing with (and missing) the full shop of 6-axis robots, huge CNCs, Objet 3D printers and more in his grad school days - i’ve been catching up and getting my hands dirty with it all through our NOTlabs projects! So when the awesome folks at Roland offered to lend us their Roland MODELA Pro II MDX-540S desktop mill, we were ecstatic! While we’ve been doing a lot of 3D printing (remember the Nescafe Alarm Caps and Free Universal Construction Kit?) - as crazy as you can get with additive processes, there’s a lot that subtractive can do (and in some cases, do better!)

There’s a CNC mill in NOTlabs! While Shawn has been playing with (and missing) the full shop of 6-axis robots, huge CNCs, Objet 3D printers and more in his grad school days - i’ve been catching up and getting my hands dirty with it all through our NOTlabs projects! So when the awesome folks at Roland offered to lend us their Roland MODELA Pro II MDX-540S desktop mill, we were ecstatic! While we’ve been doing a lot of 3D printing (remember the Nescafe Alarm Caps and Free Universal Construction Kit?) - as crazy as you can get with additive processes, there’s a lot that subtractive can do (and in some cases, do better!)

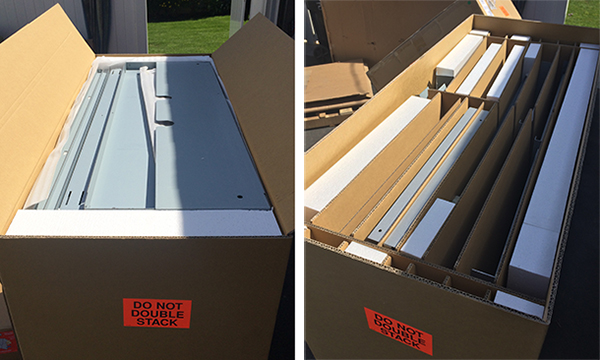

We’ve been in the getting-to-know-you phase with this “desktop” beast of a CNC recently, but to catch you up - here’s the unboxing of what two shipping palettes in the driveway is like. We definitely needed to bring in an extra pair of hands to help move the machine itself. In addition to the Roland MODELA Pro II MDX-540S main mill, there is the case, the automatic tool changer, the rotary (4th axis!) and then a starter set of various bits… and of course, Roland’s software to get to know. Ooh and then there’s also various materials to try!

First impression? SO MESMERIZING! We’ve been spending hours and hours working alongside the machine to keep an eye on things, and experimenting with a few models to test out how it handles various types of curves, materials, and details. See the full unboxing and a peek at our experiments so far on the next page!

Here’s what arrived…

Unboxing the main box with the machine itself inside…

The packaging for the case!

Getting the machine inside (it weighs a few hundred pounds!) and setting up the case around it in our machine room.

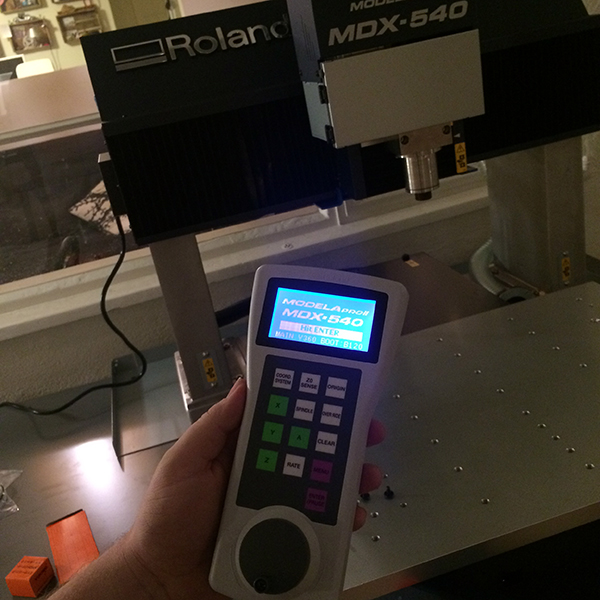

The controller, cords, CD, manuals… (FYI we had to go hunting online for drivers, and ended up finding the Win 8 drivers for this model on the Japanese site.)

Bits + more!

It works!

Fully assembled with the case - Bucky popping up to see what’s going on.

No detail is overlooked - these blue retainers are necessary for moving/repacking the machine.

Next step is hooking up the Automatic Tool Changer and our air compressor.

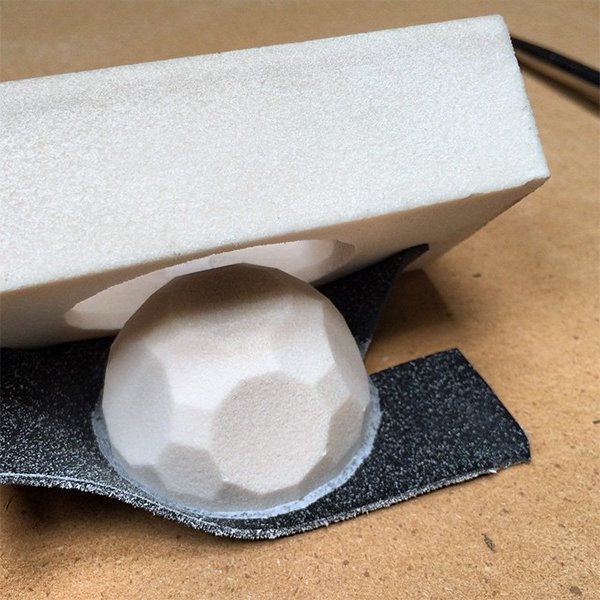

Before moving on to adding the Rotary, we’ve been testing things out and focusing on getting to know the details of how/what the Roland MODELA Pro II MDX-540S and its software can do. First step was building, attaching and leveling the spoil board. Then time to test out some geometric shapes in foam!

The level of detail is impressive.

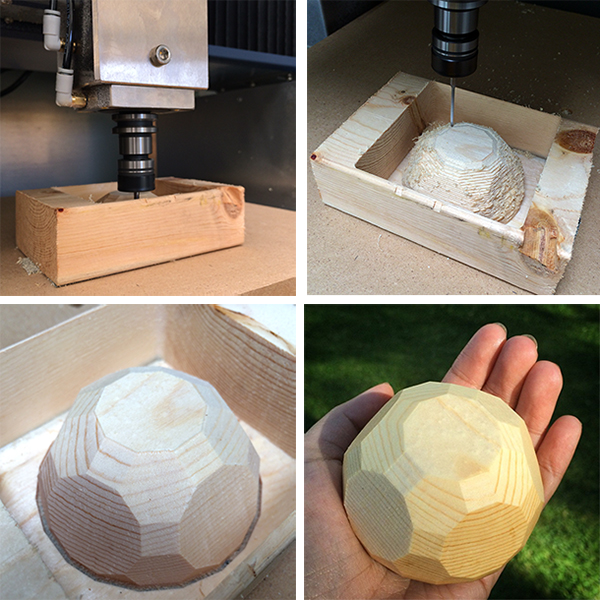

Next we tried out sticking a piece of 2x4 in…

… pretty stunning how it looks with a clear stain at the end.

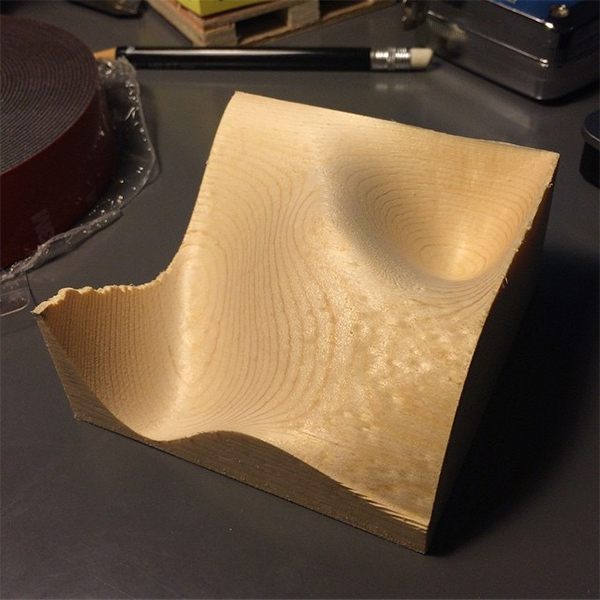

Then testing out how it handles double curvature on another piece of 2x4 (quite well!)…

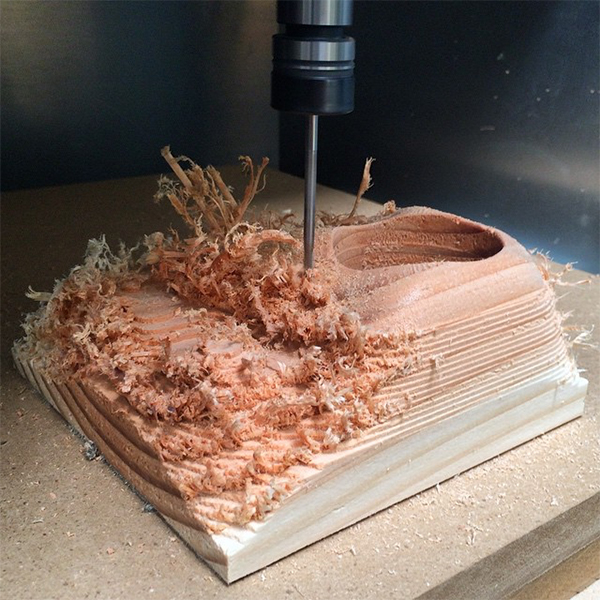

… and we’re currently running a few more tests… and perfecting all the settings. Obviously moving a little fast on the rough cut here!

So that’s the update for now - more to come soon!

Love it! I’m looking into getting one of these. Are you aware of any other companies that have the same capabilities as the Roland MDX? I’m having trouble finding any other piece of equipment that comes close to this. Any insights would be appreciated. Thanks!

----- CM 02.09.16 13:06